Price is ex-Adelaide

(Please note this item requires a forklift to unload. Please contact us for freight costs)

CNC Welded Steel Frame Construction

Includes Table Winch System, Pressure Gauge & Bending Blocks

Overview

The Metalmaster HP-45P 45 tonne workshop press has a variety of uses, ideal for removing and installing bushes, ball joints, bearings, gears, pulleys etc. The HP-45P is pneumatically or hand operated for easy of use and includes a hydraulic bypass to insure the hydraulic are not overloaded.

This 45 tonne press is manufactured from heavy duty C channel steel with a CNC welded frame for the highest quality and accuracy. The press is supplied with a winch making tabled height adjustments effortless. The press also includes a pressure gauge, two heavy duty pressing plates, and can be fitted with an optional pneumatic foot pedal, making it ideal for mechanics, farmers or the serious home workshop.

Features

- Ideal for removing and installing - Bushing, Ball-joints, Bearings, Gears, Pulleys, etc

- Pneumatic or hand operation

- Heavy duty construction with head and table all made from heavy C channel steel with CNC welded frame

- Table height adjustment via winch

- Hydraulics assembled in a temperature controlled clean room for maximum quality

- Hydraulics individually factory tested prior to shipping.

- Hydraulic bypass to avoid overloading

- Metric / imperial pressure gauge included

Includes

- Complete with bending blocks

| Pressing Capacity |

45 |

| (Type)Hydraulic Ram Operation |

Manual Hand Lever /

Pneumatic System |

| (Yes / No)Sliding Ram (left-right) |

No |

| (mm)Width Between Front Posts |

825 |

| (mm)Width Between Side Posts |

185 |

| (mm)Table Top Opening - (Front to Back) |

195 |

| (mm)Ram To Table (Max.) |

855 |

| (mm)Piston Ram Stroke |

190 |

| (mm)Ram Diameter |

Ø53 |

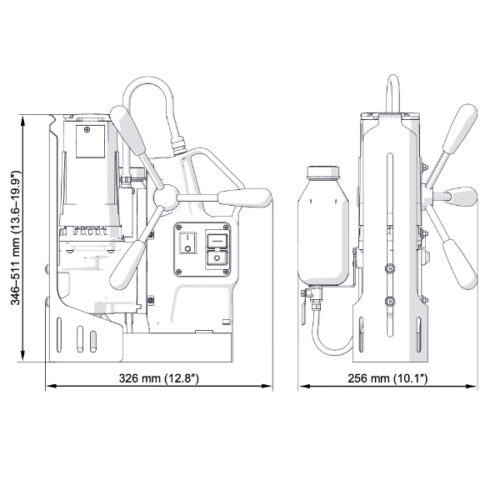

| (mm)Floor Space (W x D x H) |

1550 x 1050 x 1720 |

| (mm)Shipping Dimensions (L x W x H) |

1040 x 390 x 1900 |

| (kg)Nett Weight |

340 |