(Please note this item requires a forklift to unload. Please contact us for freight costs)

Overview

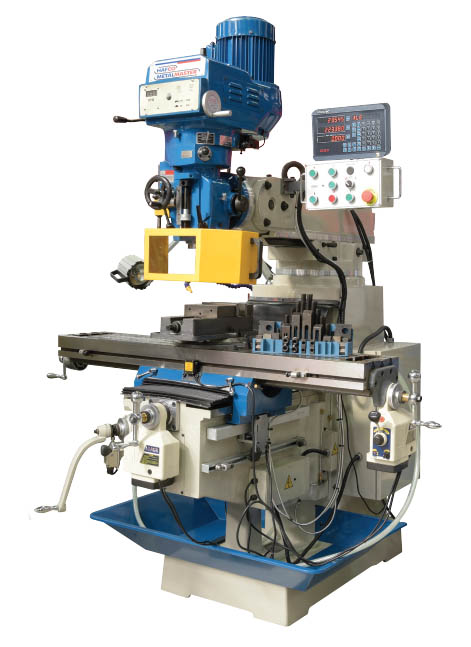

Manufactured in Taiwan

Features

- 3 Axis digital readout fitted,

- 5HP 415V motor, inverter control variable speed system with automatic spindle brake (BM-70VE)

- High quality spindle speed control with digital readout

- NT40 Spindle taper with a 105mm chrome & ground quill

- Digital spindle speed readout

- Hardened & ground work table & slide-ways

- Square construction slides for X & Z axis to maximise rigidity

- Turcite B coated X & Y-Axis slide-ways reduces friction for smooth operation

- Pneumatic operation drawbar system for quick and effortless tool change

- Powered elevating motor for Z-Axis

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a rotating base allowing repositioning of spindle

- The ram incorporates a tail lug (spigot) to accept a slotting attachment etc.

- High / neutral and low gear selection lever to maximise torque

- Inverter controlled feed motors on X & Y-Axis

- Micro switch on the manual knee handle for additional operator safety

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.04, 0.08, 0.13mm/rev

- Automatic cut off depth stop on quill

- Automatic oil lubrication pump and reservoir

- Slide-way covers Y & Z-Axis

- Mill head tilts to ±45º forward and back

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Tool box and manual

| ORDER CODE | M630D |

|---|---|

| MODEL | BM-70VE |

| Digital Readout | 3-Axis Digital Readout |

| Type | Vertical |

| (mm)Table Size | 1500 x 305 |

| Spindle Taper - Vertical | NT40 |

| (mm)Longitudinal Travel (X-Axis) | 1050 |

| (mm)Cross Travel (Y-Axis) | 420 |

| (mm)Vertical Travel (Z-Axis) | 500 |

| Type of Slides | Dovetail (X), Square (Y & Z) |

| (mm)Ram Travel | 485 |

| (mm)Spindle to Table | 460 |

| (mm)Spindle Travel / Diameter | 155 / 105 |

| (mm)Throat Depth (max.) | 750 |

| Tilting Head (Left ~ Right) | ±90º |

| Tilting Head (Forward ~ Back) | ±45º |

| (mm/rev)Power Feed - Quill | 0.04 / 0.08 / 0.13 |

| (mm/min)Power Feed - Longitudinal (X-Axis) | 30 - 3000 |

| (mm/min)Power Feed - Cross (Y-Axis) | 30 - 3000 |

| (mm/min)Power Feed - Vertical (Z-Axis) | Rapid |

| (inch / mm)Table T-Slot Size | 5/8 |

| (kg)Work Table Load Capacity | 500 |

| (No./ rpm)Spindle Speeds Vertical | Inverter (70 - 4200) |

| (kW / hp)Motor Power - Vertical | 3.75 / 5 |

| (V / amp)Voltage / Amperage | 415 |

| (cm)Shipping Dimensions (L x W x H) | 160 x 170 x 240 |

| (kg)Nett Weight | 1800 |