Price is ex-Adelaide

(Please note this item requires a forklift to unload. Please contact us for freight costs)

Overview

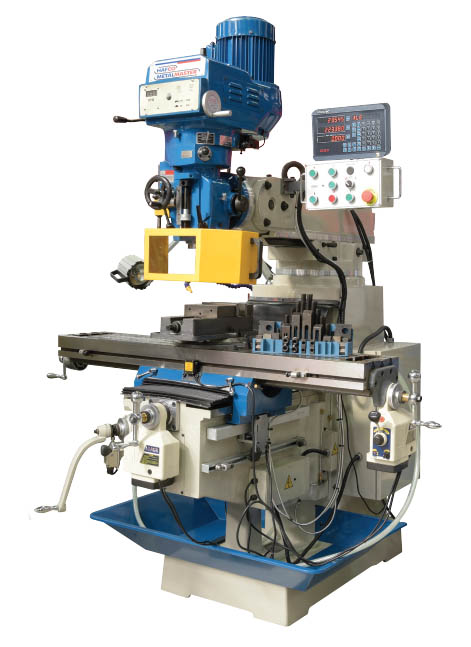

This HM-54GV geared head vertical and horizontal turret milling machine now includes a inverter variable speed drive on the vertical spindle, with a powerful continuous-load 2.2kW / 3hp vertical motor and a 2hp motor for the horizontal spindle, intended for trade use. The work table is precision made with adjustable dovetail guides and is recognised for its 600mm X axis by 200mm Y axis travel. There is a three armed handle on the side for drilling also incorporating a fine feed control hand wheel on the front for milling. The hi-low geared head selector lever mounted on right side of milling head allows for quick change off speed range.

Other features include 3-Axis digital readout system, taper roller bearing support for the spindle, easy-to-read drilling depth stop, low voltage LED work light, coolant system, X axis power feed unit, drill chuck, 1″ & 1-1/4″ horizontal arbors, 2 & 3 morse taper adaptors. The combination of generous sized vertical support and rugged cast iron construction throughout reduces vibration and guarantees accurate and chatter-free operation.

Extra Features:

Swivel table

1″ & 1-1/4″ horizontal arbors

Features

-

- Electronic inverter variable spindle speeds

- 3 Axis digital readout system

- Swivel table left & right with graduated scale

- Mill head tilts to ±45º left to right

- 450mm horizontally sliding and rotating ram

- NT30 Horizontal and vertical spindles that are hardened and ground

- Precision-ground dovetail slide-ways and table

- Precision milling table incorporating machined T slots

- Rear concertina slide-way cover

- Forward and reverse button switch

- Fine hand wheel operated quill feed

- Swarf & splash tray

- Spindle lock for quill

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Vertical quill hand-wheel dial graduations @ 0.05mm

- All slides utilise dovetail construction for maximum rigidity

- Includes 1″ & 1-1/4″ arbors for the horizontal spindle

- * Note: X & Y travels maybe reduced due to digital readout scales and safety stops

- * Note: Optional Y & Z power feeds require additional parts & fitting (not included)

Includes

- Electronic inverter variable spindle speeds

- 3 Axis digital readout system

- X-Axis power-feed

- Safety cutter guard

- Swarf tray

- Coolant system

- LED work light

- Drill chuck & arbor

- NT30 to 3MT adaptor

- 2MT & 3MT adaptors

| MODEL | HM-54GV |

|---|---|

| Digital Readout | 3-Axis Digital Readout |

| Type | Vertical & Horizontal |

| (mm)Table Size | 1000 x 240 |

| Spindle Taper – Vertical | NT30 |

| Spindle Taper – Horizontal | NT30 |

| (mm)Longitudinal Travel (X-Axis) | 600* |

| (mm)Cross Travel (Y-Axis) | 200* |

| (mm)Vertical Travel (Z-Axis) | 340 |

| Type of Slides | Dovetail |

| (mm)Ram Travel | 450 |

| (mm)Spindle to Table | 375 |

| (mm)Spindle Travel / Diameter | 120 / 90 |

| (mm)Throat Depth (max.) | 640 |

| Tilting Head (Left ~ Right) | ±45º |

| Tilting Head (Forward ~ Back) | Fixed |

| (mm)Drilling Capacity | 40 |

| (mm)End Milling Capacity | 25 |

| (mm)Face Milling Capacity | 80 |

| (mm/rev)Power Feed – Quill | Manual |

| (mm/min)Power Feed – Longitudinal (X-Axis) | 20 – 2000 |

| (mm/min)Power Feed – Cross (Y-Axis) | Optional * |

| (mm/min)Power Feed – Vertical (Z-Axis) | Optional * |

| (inch / mm)Table T-Slot Size | 14 |

| (kg)Work Table Load Capacity | 160 |

| (No./ rpm)Spindle Speeds Vertical | Variable (100 – 2000) |

| (No./ rpm)Spindle Speeds Horizontal | 9 (60 – 1350) |

| (kW / hp)Motor Power – Vertical | 2.2 / 3 |

| (kW / hp)Motor Power – Horizontal | 1.5 / 2 |

| (V / amp)Voltage / Amperage | 240 / 10 |

| (cm)Shipping Dimensions (L x W x H) | 134 x 114 x 225 |

| (kg)Nett Weight | 900 |