Price is ex-Adelaide

(Please note this item requires a forklift to unload. Please contact us for freight costs)

Overview

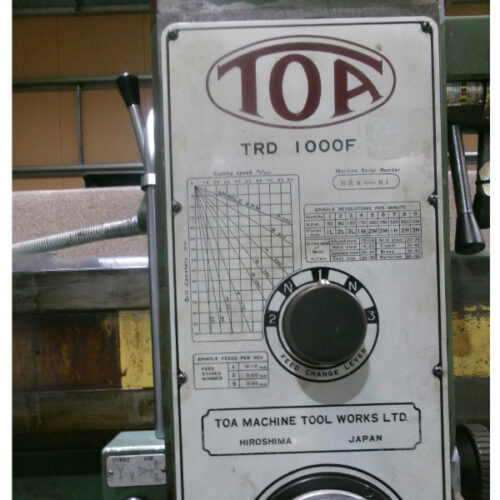

Floor standing, heavy duty metal turning lathe suitable for the keen model engineer and general maintenance work shops. Featuring a precision ground, induction hardened bed, fully gear driven spindle with a speed range of 65 - 1810rpm, selectable via the front of headstock mounted gear selection levers.

2HP single phase 240V motor is supplied on machine, taper roller spindle bearings, range of cross and longitudinal feed speeds selected on a separate gearbox, thread chasing dial, spindle foot brake, chuck guard with safety interlock, guarded leadscrew, splash guard, coolant pump system, work lamp, digital readout on a separate panel.

Supplied with a large range of standard accessories including a 150mm(6") 3 jaw self centring chuck, 200mm(8") 4 jaw independent chuck, face plate and dead centres. 5 to 3 MT reduction sleeve, steady rest, follow rest, quick change tool post with 4 tool holders. The floor stand is supplied with a swarf tray and incorporates a foot brake. Change gears and toolbox with maintenance tools.

The overall capacities are 900mm between centres and 300mm swing over the bed. A gap bed facility gives 450mm swing. Thread cutting facilities in Metric & Imperial with a reversible leadscrew, the thread chasing dial provides easy re-engagement of the leadscrew in the correct position. (note the thread chasing dial is designed for imperial only).

Features

- 2 Axis digital readout

- Quick change toolpost with 4 holders

- Gear drive headstock for quick change of spindle speeds

- Precision 'V'-beds are hardened and ground, incorporating a rigid webbed casting

- Concertina leadscrew cover

- Slide out swarf tray from front of machine

- Low voltage work light

- Foot operated spindle brake with safety cut out switch

- Slide out front swarf tray for easy cleaning

- Change gears for metric and imperial thread cutting

- Oil sight glass for head stock and gearbox

- Adjustable taper roller bearings support the spindle

- 18 spindle speeds from 65 to 1810rpm

- Inching button is incorporated on the control panel for convenient spindle speed selection

- Enclosed quick action gearbox for thread cutting and auto feeding

- Powered longitudinal and cross feeds

- D1-4 camlock spindle for quick chuck changes and safe reverse direction turning. ISO standard

- Removable gap bed-way for larger diameter jobs

- Dual calibrated dials (except for saddle hand-wheel)

- Chuck & change gear guards are fitted with micro switches

Specifications

- 300mm swing over bed

- 900mm between centres

- 38mm spindle bore

- 450mm swing in gap

- 180mm swing over cross slide

- 170mm cross slide travel

- 75mm compound slide travel

- Imperial cross feed: 0.009-0.236inch/rev

- Imperial longitudinal feed: 0.04-1.2236inch/rev

- 150mm centre height

- Tool height suits 12mm tools

- 5MT headstock

- 3MT tailstock

- Imperial leadscrew

- Metric thread steps and pitch: 32 (0.4-7)

- Imperial thread steps and TPI: 36 (4-60)

- Spindle speeds: 18 (65-1810)

- 2HP 240V motor

Includes

- 2 Axis digital readout system

- Concertina leadscrew cover

- Quick change toolpost with 4 holders

- Slide out front swarf tray

- 3-jaw chuck with reverse jaws

- 4-jaw chuck

- Face plate

- Fixed steady

- Travelling steady

- Coolant system

- Change gears

- Dead centres

- Thread-chasing dial

- Safety chuck guard

- Work light

- Stand

- Foot brake

- Rear splash guard & slide out swarf tray

- Tool box

- Instruction booklet