- 500mm stroke

- Power and rapid feed

- 5.5KW 415V motor

-

FEATURES

New generation machines with the latest technology and design.- New Rigid Frame Design Provides increased life of cutting tools.

- New Extra Large 165mm Stroke Enables the use of long tooling such as extension arbors and large depth cutters for drilling box section steel in one pass, twist drills, reamers, taps etc.

- Magnetic Field Shape Control (MFSC) Provides maximum holding power on thin materials.

- Lightweight & Powerful The new generation Holemaker machines are lighter and more powerful than other brands on the market.

- Multi-purpose machine able to use Holemaker cutters, no. 2 Morse taper shank drills & reamers, as well as a drill chuck

- Industrial 2-speed gearbox

- Cast-iron motor housing

- Through spindle coolant system, with an external side mounted gravity feed coolant tank

- Left or right hand feed handle operation

- Unique semi-automatic gib adjustment system enables simple, fast and always correct fine tuning without any expert knowledge or experience

- Smart magnet technology to ensure sufficient magnetic adhesion

- Supplied in a blow mould plastic carry case

- Suitable for steel fabrication, engineering workshops & maintenance facilities where a heavy-duty versatile machine is highly beneficial

- Supplied complete with arbor for use with Holemaker cutters up to 50mm depth of cut (3/4" shank)

- #2MT drill chuck SA20102 available separately

SPECIFICATIONS

- Capacity (Diameter): 52mm

- Capacity (Depth): 52mm

- Capacity (Twist Drills): #2 Morse Taper 23mm

- Motor Power: 1100 Watt

- Input Power: 1200 Watt Single Phase 240V

- Speed: 2 Speed 240 / 480rpm

- Weight: 16.5kg

- Magnetic Dead Lift: 9,900Nm On 25mm Steel Plate

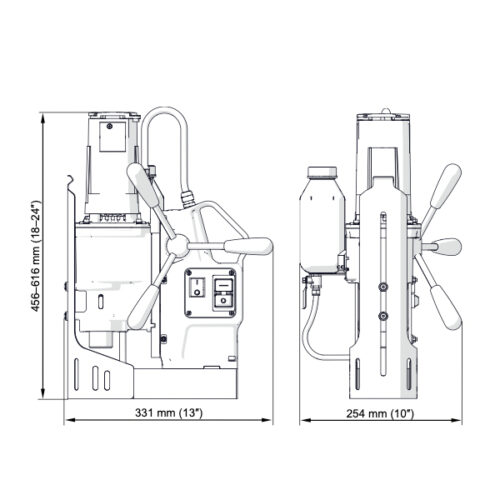

- Stroke: 165mm

- Height (Min. / Max.): 456mm / 616mm

-

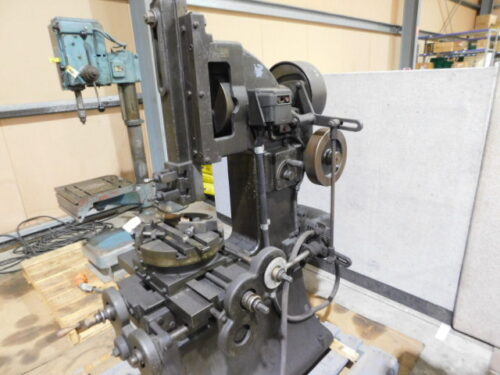

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)320 swing over bed600mm between centres38mm spindle bore210mm swing over cross slide150mm cross slide travel100mm compound slide travelMetric cross feed: 0.022-0.15 mm/revMetric longitudinal feed: 0.1-1.4 mm/rev160mm centre heightTool height suits 12mm tools5MT headstock3MT tailstockMetric leadscrewMetric thread steps and pitch: 11 (0.5-4.0)Imperial thread steps and TPI: 27 (9-48)Spindle speeds: 12 (60-1600rpm)1HP 240V motor

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)320 swing over bed600mm between centres38mm spindle bore210mm swing over cross slide150mm cross slide travel100mm compound slide travelMetric cross feed: 0.022-0.15 mm/revMetric longitudinal feed: 0.1-1.4 mm/rev160mm centre heightTool height suits 12mm tools5MT headstock3MT tailstockMetric leadscrewMetric thread steps and pitch: 11 (0.5-4.0)Imperial thread steps and TPI: 27 (9-48)Spindle speeds: 12 (60-1600rpm)1HP 240V motorFeatures

- Geared headstock for quick change of spindle speeds

- Hardened and ground bed

- Adjustable taper roller spindle bearings

- Metric & imperial thread cutting

- Powered longitudinal and cross feed

- Head stock oil sight glass

- Thread chasing dial

- Quick action tailstock locking lever

- Forward/reverse spindle switch

Includes

- 160mm 3-jaw chuck with reverse jaws

- 200mm 4-jaw chuck

- Face plate

- Fixed steady

- Travelling steady

- Change gears

- Dead centre

- Rear splash guard & swarf tray

- Spanners

- Tool box

- Safety chuck guard

- Instruction booklet

Optional Accessories

- Lathe stand to suit (L142)

-

Sale!

- 2-step variable speed oil bath gearbox

- Forward-reversible drive-ideal for tapping

- 3 coil 16000N magnetic adhesion

- Morse taper 2 spindle

- Solid brass guides

- Core drilling: 12-50mm (with optional core drill attachment)

- Cutting depth: 50mm

- Twist drill capacity: 20mm MTS

- Tapping: M3-M20 with optional tapping attachment

- Stroke: 170mm

- Height adjustment: 100mm

- 4 speed gearbox: 100-250rpm/180-450rpm (2 step)

- 1,200W motor

- 230V

- Magnetic base: 92mm x 238mm

- Weight: 16kg

-

- Swivel head enables from 0° to 60° mitre cuts.

- Dual mode operation. - Trigger switch with manual down feed for small quick cuts. - Control panel with fully adjustable hydraulic down feed & automatic shut-off at end of cut, for cutting larger material.

- Incorporated recirculating coolant system.

- Brass chip brush to help prevent blade breakage.

- Adjustable material stop for repetitive production.

- Safety emergency stop switch.

- 12 months warranty.

- Comes complete with stand & blade.

- Optional blade tension gauge.

- Made in Taiwan.

-

(Please note this item requires a forklift to unload. Please contact us for freight costs. Price is ex Adelaide)

(Please note this item requires a forklift to unload. Please contact us for freight costs. Price is ex Adelaide)GHD-30V - Industrial 3MT Geared Head & Variable Speed Drilling Machine

31.5mm Drilling CapacityIncludes Automatic Feed & TappingFeatures

- 31.5mm drill capacity with 125mm spindle travel

- Geared head drilling machine with low, medium, & high selector

- Electronic variable speed from 50-2850rpm with digital display

- Automatic start drill function for repetition work

- Automatic Power Feed with range of (0.06, 0.09, 0.12mm/rev)

- Thread tapping with auto reverse

- Digital readout depth gauge mounted on front panel

- Adjustable accurate depth setting for increased productivity

- Chuck guard with safety micro-switch

- Drill ejector incorporated in machine

- Work light mounted in convenient location

- T slotted work table & base

- Rack & pinion wind-up table

- Square work table tilts to ±45º & rotates 360º

- Coolant pump system with flexible hose

- 2.2kW / 3hp motor 240V

- Includes 16mm keyless drill chuck and arbor

Includes

- Coolant pump system

- 16mm keyless drill chuck and arbor

- Safety chuck guard

MODEL GHD-30V (mm)Drilling Capacity 31.5 (Metric)Thread Tapping Capacity M20 (MT)Spindle Taper 3 (mm)Spindle Travel 125 (mm)Throat Depth 285 (mm)Quill Diameter 62 (mm)Column Diameter 115 (mm)Spindle To Table 790 (mm)Spindle To Base 1270 (Type)Table Rectangle (mm)Table Size 426 x 400 (mm)T-Slot Size 14 (mm/rev)Automatic Quill Feed 0.06, 0.09, 0.12 (Includes)Work Light Yes (Includes)Coolant System Yes (No.)Spindle Speed Steps Variable (3 Steps) (rpm)Spindle Speed Range 50 ~ 2850 (kW / hp)Motor Power 2.2 / 3 (V / amp)Voltage / Amperage 240 / 15 (mm)Full Height 1940 (cm)Shipping Dimensions (L x W x H) 86 x 60 x 210 (kg)Nett Weight 368 -

(Please note this item requires a forklift to unload. Please contact us for freight costs)

(Please note this item requires a forklift to unload. Please contact us for freight costs)- 315mm blade

- 3HP 415V three phase motor

- 2 speed 20/40rpm slow speed for cutting stainless steel

- 80mm x 80mm (115mm x 70mm) @ 90°

- 70mm x 70mm @ 45°

- 90mm round (55mm solid) @ 90°

- 80mm round (50mm solid @ 45°

- Italian made quality

- Recirculating coolant system with electric pump – Creates instant flow of coolant – Flood applied coolant creates a cooler cut, for increased finish quality & blade life

- Swivel head 45° left & right

- Trigger switch operation

- Quick locking double vice for burr free cutting

- Incorporated recirculating mechanical coolant system supplying coolant to both sides of the blade

- Adjustable material stop for repetitive production

- Comes complete with blade

- Optional stand available – part# MC-STAND315

-

(Please note this item requires a forklift to unload. Please contact us for freight costs)

(Please note this item requires a forklift to unload. Please contact us for freight costs)Includes Automatic Feed & Tapping

Features

- Ideal for industrial workshop use

- Geared head drilling machine with 4 morse taper spindle

- Thread tapping with auto reverse

- Automatic feed range (0.1, 0.2mm/rev)

- 18 drilling speeds from 50-1450rpm

- Chuck guard with micro-switch

- Drill ejector incorporated in machine

- Coolant pump system with flexible hose

- Work light mounted in convenient location

- 40mm drill capacity with 180mm of Spindle travel

- Oil sight glass for geared head and feed gearbox

- Modern electrics to european CE standards

- Forward and reverse spindle switch with high and low speeds

- Emergency stop switch and overload protection

- Substantial heavy walled column ensuring greater rigidity

- Adjustable accurate depth setting with auto feed cut out for increased productivity

- Rack and pinion wind-up table

- T slotted work table and base

MODEL GHD-38B (mm)Drilling Capacity 40 (Metric)Thread Tapping Capacity M24 (MT)Spindle Taper 4 (mm)Spindle Travel 180 (mm)Throat Depth 350 (mm)Quill Diameter 75 (mm)Column Diameter 150 (mm)Spindle To Table 770 (mm)Spindle To Base 1320 (Type)Table Square (mm)Table Size 560 x 560 (mm)T-Slot Size 16 (mm/rev)Automatic Quill Feed 0.1, 0.2 (Includes)Work Light Yes (Includes)Coolant System Yes (No.)Spindle Speed Steps 18 (rpm)Spindle Speed Range 50 - 1450 (kW / hp)Motor Power 1.5 / 2 (V / amp)Voltage / Amperage 415 (mm)Full Height 2220 (cm)Shipping Dimensions (L x W x H) 227 x 69 x 110 (kg)Nett Weight 615