Price is ex-Adelaide

(Please note this item requires a forklift to unload. Please contact us for freight costs)

Overview

The MBR-610 motorised bead roller is much easier to use compared to manual machines to having your panels beaded in your home workshop or garage. Made from heavy plate steel and a massive 610mm throat depth making it perfect for strengthening any type of car roof, body panels, seals & guards etc.

This bead roller is electrically gear driven via a forward & reverse foot control switch that drives both the bottom and top bead rolls. The drive shafts are supported in quality bronze bearing bushes and incorporate with thrust ball bearings for additional support & accuracy.

The MBR-610 also includes a stand that also stores the twelve sets of the most common rolls required by any metal forming automotive enthusiasts or professional.

Features

- 1.2mm mild steel capacity with 610mm throat

- Variable speed dial for superior control on all applications

- Forward / reverse foot pedal switches with emergency stop

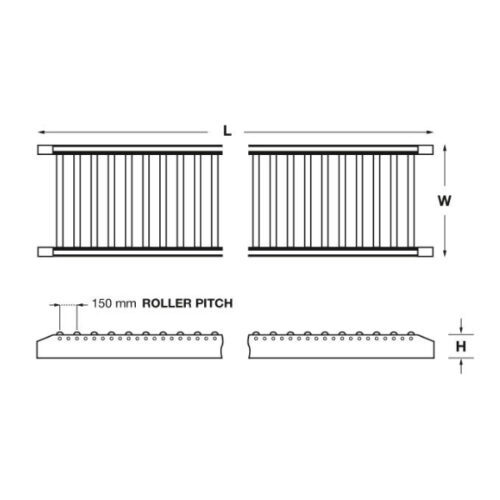

- Ø70mm hardened & keyed rollers for positive drive

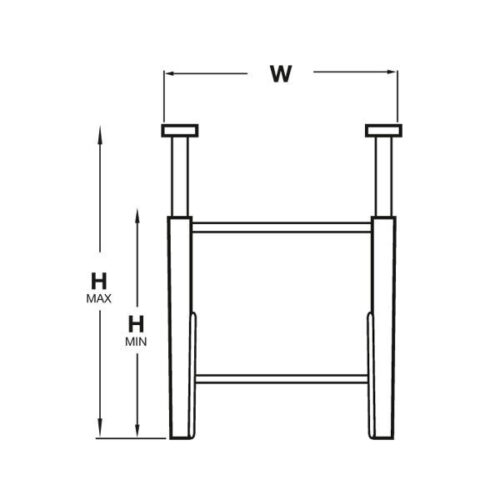

- 105mm gap height between roller support arms

- Allows clearance of up to 80mm on 90º return bends

- Heavy duty steel plate construction for increased rigidity

- Top & bottom roller shafts are geared & electrically driven

- Adjustable top roller with 38mm of vertical travel

- Top shaft adjusts horizontally to easily & accurately align dies

- Ø25mm drive shafts with grease-able bronze bushes, Ø20mm spigot for mounting rollers

- Adjustable material depth guide

- 0.25kW / 0.33hp, 240V variable speed motor with reduction gearbox

- Fitted with two rear wheels to allow easy mobility

- Includes a comprehensive range of rolls supplied as standard

Includes

- 12 sets of hardened rolls (Ø20mm Bore):

- 5/32" (4mm) beading dies

- 1/4" (6.35mm) beading dies

- 3/8" (9.5mm) beading dies

- 15/32" (12mm) beading dies

- 19/32" (15mm) beading dies

- 1/16" (1.6mm) flanging dies

- 1/8" (3mm) flanging dies

- 1/4" (6.35mm) flanging dies

- 3/8" (9.5mm) flanging dies

- Ogee beading dies

- Wiring dies

- Shearing dies