- Swivel head enables from 0° to 60° mitre cuts.

- Dual mode operation. - Trigger switch with manual down feed for small quick cuts. - Control panel with fully adjustable hydraulic down feed & automatic shut-off at end of cut, for cutting larger material.

- Incorporated recirculating coolant system.

- Brass chip brush to help prevent blade breakage.

- Adjustable material stop for repetitive production.

- Safety emergency stop switch.

- 12 months warranty.

- Comes complete with stand & blade.

- Optional blade tension gauge.

- Made in Taiwan.

-

-

FEATURES:

FEATURES:- Manual Control Panel - Only control panel with buttons.

- Inverter - Provides to adjust blade speed up to workpiece diameter, thickness and hardness.

- Hydraulic Vise - Pressure, clamping period and clamping time can be adjusted.

- Swarf Brush - Removes swarfs to keep clean the wheels and blade.

- Hydramechanical Blade Tensioning - Tensioning period and tensioning time can be adjusted. So blade does not relax and curve cutting gets prevented.

- Blade Bedding with Carbide and Bearings

- Rotating Table

- 60 cm Long Material Stopper System

- Bevel Helical Gearbox

- Moveable Guide Arms

- Adjustable Bow Down Speed

- Adjustable vise Tension

- Easy Readable Angle Ruler

- Main Motor : 4 kW

- Gearbox : Bevel Helical PKD 2390 High Efficiency

- Hydraulic Motor : 0,37 kW

- Hydraulic Tank Capacity : 8 Liter

- Coolant Motor : 0,12 kW

- Coolant Tank Capacity : 30 liters

- Blade Speed : 25-90 m/min

- Blade Dimensions : 4780 x 34 x 1,1 mm

- Machine Weight : 1.350 kg

- Machine Dimensions : 1400 x 2350 x 1500 mm

- Table Height : 750 mm

-

Benefits:

Benefits:- Control Panel – easy to reach and easy to control

- Coolant Pump - fitted with a removable coolant tank incorporating a submerged electric coolant pump which supplies coolant to both carbide guide assemblies

- Powerful motor with variable speed 20-90 m/min

- Heavy Duty direct dive gearbox – built tough – can cut all day non-stop

- Blade guides with rollers and carbide pads provide precise support for the blade guarantee longer blade life.

- Variable speed – giving you a clean and fast cut for all materials, from aluminium to stainless steel to induction harden chrome bar

- Blade brush to keep the blade clean from swarf

- Low working height - only 730mm

- Height adjustment switch to save you time when cutting smaller jobs

- Hydromechanic Blade Tension – gives you the correct amount of blade tension, critical for straight cuts and longer blade life

- Material Limit Shaft – machines stops once the cut is completed

- Automatic blade break protection

- Constructed in heavy gauge steel, giving you a strong rigid saw frame, providing a high degree of accuracy when cutting.

- Motor - 1.5kW (415v - 3phase)

- Blade Speed - 25 - 90 m/min (variable)

- Blade Dimensions - 3150 x 27 x 0.9 mm

- Machine Weight - 480kg

- Machine Dimensions - 750 x 1650 x 1150 mm

- Table Height - 730 mm

-

- Up to 60° mitre cutting

- Variable Speed 25-100m/min

- Quick lock vice

- Coolant System

- Digital Display

- Includes stand

- Cast Iron saw frame

- Carbide blade guides

- Low voltage electrics

- Emergency Stop

- Automatic (variable) down feed

- 250mm vice opening

- Mechanical blade tension microswitch

- Includes infeed roller, 500mm adjustable end stop & one blade fitted

-

Out of stock

- 875mm length

- 38mm W

- 28deg

- Suits Delta 3VH and others

-

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)-

- Dual miter 60° to -45°

-

- Quick lock vice

-

- Coolant System

-

- Digital Display

-

- Includes stand

-

- Cast Iron saw frame

-

- Carbide blade guides

-

- Low voltage electrics

-

- Emergency Stop

-

- Automatic (variable) down feed

-

- 245mm vice opening

-

- Mechanical blade tension microswitch

-

- Includes infeed roller, 500mm adjustable end stop & one blade fitted

-

-

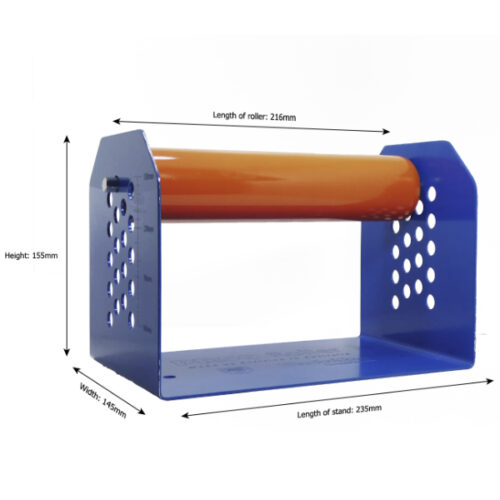

The Excision Portable PR-50 Roller is a versatile, lightweight cutting tool designed for on-site applications. Made in Australia, this fully adjustable roller boasts a huge height range of 60mm to 150mm, making it compatible with all portable bandsaws and drop saws. Its lightweight design makes it easy to carry and transport, while its four positioning holes allow for secure fixing to saw horses, providing added stability and precision while in use. This portable roller is perfect for any cutting job on site, whether it's for construction, remodeling, or DIY projects. With the Excision Portable PR-50 Roller, you'll have a reliable and efficient cutting solution at your fingertips.

The Excision Portable PR-50 Roller is a versatile, lightweight cutting tool designed for on-site applications. Made in Australia, this fully adjustable roller boasts a huge height range of 60mm to 150mm, making it compatible with all portable bandsaws and drop saws. Its lightweight design makes it easy to carry and transport, while its four positioning holes allow for secure fixing to saw horses, providing added stability and precision while in use. This portable roller is perfect for any cutting job on site, whether it's for construction, remodeling, or DIY projects. With the Excision Portable PR-50 Roller, you'll have a reliable and efficient cutting solution at your fingertips. -

Price is ex-Adelaide(Please note this item requires a forklift to unload. Please contact us for freight costs)The MBR-1070XT motorised bead roller is much easier to use compared to manual machines to having your panels beaded in your home workshop or garage. Made from heavy plate steel and a now with a massive 1070mm throat depth making it perfect for strengthening any type of car roof, body panels, seals & guards etc. This bead roller is electrically gear driven via a forward & reverse foot control switch that drives both the bottom and top bead rolls. The drive shafts are supported in quality bronze bearing bushes and incorporate with thrust ball bearings for additional support & accuracy. The MBR-1070XT also includes a stand that also stores the twelve sets of the most common rolls required by any metal forming automotive enthusiasts or professional. 1.2mm mild steel capacity.

Price is ex-Adelaide(Please note this item requires a forklift to unload. Please contact us for freight costs)The MBR-1070XT motorised bead roller is much easier to use compared to manual machines to having your panels beaded in your home workshop or garage. Made from heavy plate steel and a now with a massive 1070mm throat depth making it perfect for strengthening any type of car roof, body panels, seals & guards etc. This bead roller is electrically gear driven via a forward & reverse foot control switch that drives both the bottom and top bead rolls. The drive shafts are supported in quality bronze bearing bushes and incorporate with thrust ball bearings for additional support & accuracy. The MBR-1070XT also includes a stand that also stores the twelve sets of the most common rolls required by any metal forming automotive enthusiasts or professional. 1.2mm mild steel capacity.MODEL MBR-1070XT (Type)Machine Bead Roller - Motrised (mm / Gauge)Mild Steel - Thickness Capacity 1.2 / 18 (mm / Gauge)Aluminium - Thickness Capacity 1.6 / 16 (mm)Throat Depth Maximum 1070 (mm)Roll Diameter 70 (rpm)Output Drive Speed 0 - 18 (kW / hp)Motor Power 0.25 / 0.33 (V / amp)Voltage / Amperage 240 / 10 (kg)Nett Weight 150 Includes

- 12 sets of hardened rolls (Ø20mm Bore):

- 5/32" (4mm) beading dies

- 1/4" (6.35mm) beading dies

- 3/8" (9.5mm) beading dies

- 15/32" (12mm) beading dies

- 19/32" (15mm) beading dies

- 1/16" (1.6mm) flanging dies

- 1/8" (3mm) flanging dies

- 1/4" (6.35mm) flanging dies

- 3/8" (9.5mm) flanging dies

- Ogee beading dies

- Wiring dies

- Shearing dies

-

Out of stock

- 890mm OD

- 38mm W

- 32deg x 14T

- Suits BM-30, BM-30A, BM-40V, BM-52VE, BM-62VE and others

-

Features

- Perspex guard 285 x 180mm

- Aluminium extrusion and plastic housing has micro switch

- Retro fits to most Mill / Drilling machines

- Safety chuck guard comes complete with mounting bracket with built-in micro switch and 0.5 Metre of wiring to be connected to the electrical cabinet

- Just fasten the mounting bracket to the side of mill/drill head

- Micro switch recommended for 12V or 24V

- Installation is required by a licensed electrician