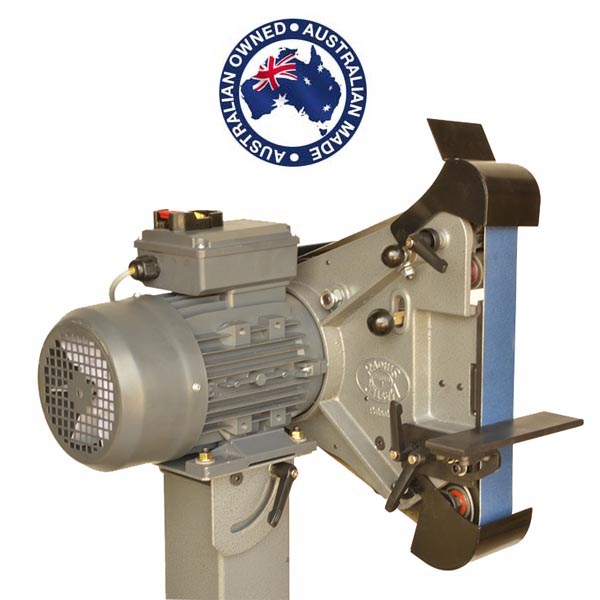

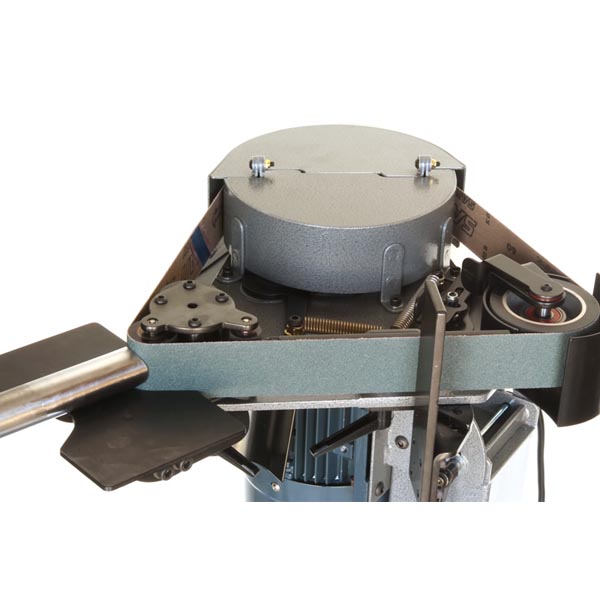

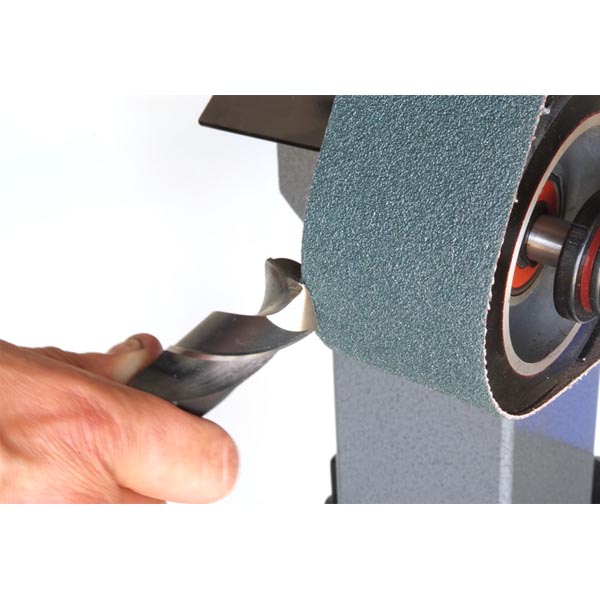

Radius Master’s unique design provides a multitude of functions via 7 work stations, each readily available in seconds and without tools, using an easy to operate index knob. Only the Radius Master brand of machines are capable of tracking the latest heavy duty polyester backed ceramic belts. 7 work stations provide a wide variety of surface finishing, intricate product de-burring, tube notching, profiling and precision sharpening of drills and cutters.

Radius Master provides accurate tracking performance, allowing notching into sharp corners for better product finishing and significant savings on consumables, such as belts and contact wheels.

Lightning fast belt changes, 7 work stations and 5 contact wheels result in savings of hours per day on many jobbing, restoration and prototype work.

Designed for engineers, fabricators, welders, fitters, balistrade and stainless specialists, foundries, toolmakers, knife makers, rural manufacturers, mechanics, restorers, aircraft engineers, medical equipment manufacturers, sculptors, model makers and manufacturers of many wood and plastic products.

The Radius Master multi station belt grinder can do it all!

RADIUS MASTER 48 SERIES 2 BELT GRINDER FEATURES:

- Internal, external and hollow grinding on 5 contact wheels

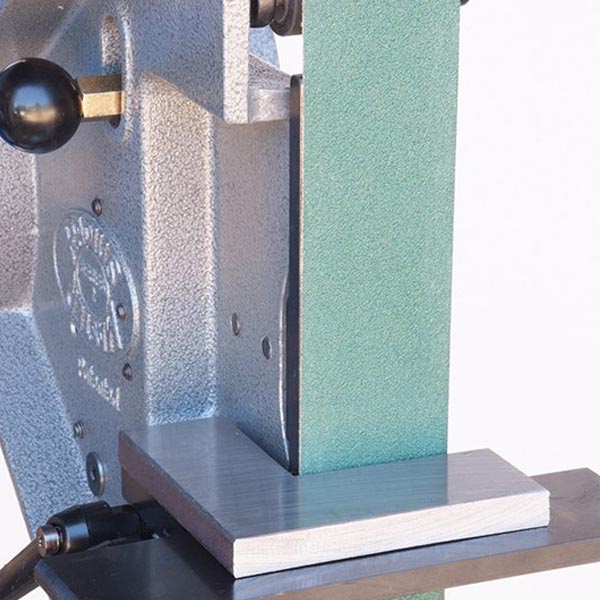

- Flat grinding in vertical and horizontal position

- Edge grinding on tool rest (tilts up 20° and down 45°)

- Slack belt grinding in horizontal and vertical positions

- Its accurate tracking is an unmatched asset in precision sharpening of small drills & cutters and allows the use of cut down belts to 8mm for finishing &deburring difficult contours.

- Tracking mechanism will never lose it’s precision as vital pivots are sealed ball bearings

Motor: 1.5KW 240V

Belt Size: 50mm x 1220mm

Belt Speed: 914MPM