- 1″ x 11.5 NPT Bottoming HSS Tap – Goliath

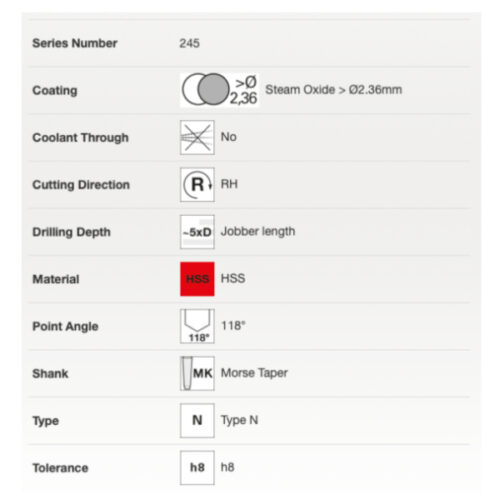

- HSS Bright Finish NPT Hand and Machine Bottoming Tap.

- Pipe taps are much shorter than a similar size of regular hand tap, but the design features are the same.

- Goliath HSS taps provide a high hardness to toughness ratio, compressive and tensile strength, good abrasion resistance and resistance to micro-chipping, ensuring a long tool life.

- Tapered Pipe Taps are used for tapered threading by hand or machine.

- National Pipe Tapered (NPT)is a US standard for tapered threads used to join pipes and fittings.

- ANSI/ASME standard B1.20.1 covers threads of 60º form with flat crests and roots.

- The taper on NPT threads allows them to form a seal when torqued as the flanks of the threads compress against each other.

- However a clearance remains between the crests and roots of the threads, resulting in a leakage around this spiral.

- This means that NPT fittings must be made leak free with the aid of thread seal tape or a thread sealant compound.

- For each 12″ increase in distance from the end, the diameter increases by 3/4″.

- Bottoming Taps have a lead of two threads and are used to ensure minimum thread run-out when tapping to the bottom of a blind hole.

- Bottoming Taps are typically preceded by the use of a Taper or Intermediate Tap.

- Manufactured from HSS this general purpose tap is designed for use in medium tensile.

- Recommended tapping drill: 29mm

Goliath 1″ NPT Taper Form Bottom Tap HSS

Original price was: $414.77.$269.60Current price is: $269.60.

Only 1 left in stock

Only 1 left in stock

Additional information

| Weight | .450 kg |

|---|---|

| Dimensions | 110 × 40 × 40 mm |