- 890mm OD

- 38mm W

- 32deg x 14T

- Suits BM-30, BM-30A, BM-40V, BM-52VE, BM-62VE and others

-

Features

- Perspex guard 285 x 180mm

- Aluminium extrusion and plastic housing has micro switch

- Retro fits to most Mill / Drilling machines

- Safety chuck guard comes complete with mounting bracket with built-in micro switch and 0.5 Metre of wiring to be connected to the electrical cabinet

- Just fasten the mounting bracket to the side of mill/drill head

- Micro switch recommended for 12V or 24V

- Installation is required by a licensed electrician

-

(Please note this item requires a forklift to unload. Please contact us for freight costs)

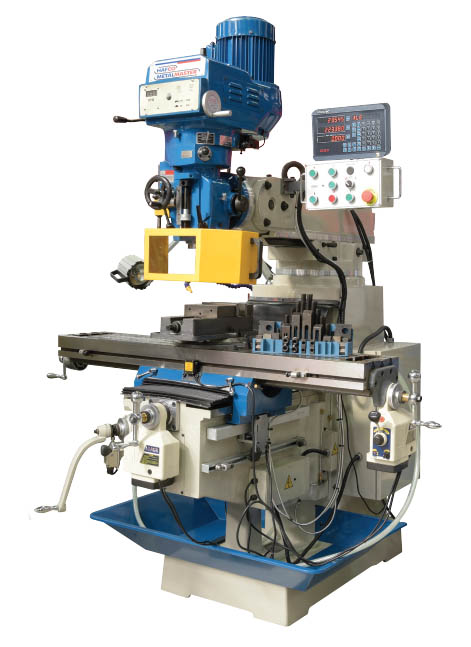

Made in TaiwanFeatures

- 3 Axis digital readout fitted

- 3HP 415V motor, dial variable speed system (BM-40V)

- NT30 spindle taper with a chrome & ground quill

- Hardened & ground work table & slide-ways

- Turcite "B" coated X & Y Axis slide-ways reduces friction for smooth operation

- All slides utilise dovetail construction for maximum rigidity

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a rotating base allowing repositioning of spindle

- The ram incorporates a tail lug (spigot) to accept a slotting attachment etc.

- High / neutral and low gear selection lever to maximise torque

- Align AL-500S X-Axis power-feed with adjustable micro switch feed stops

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.015, 0.04, 0.08mm/rev

- Automatic cut off depth stop on quill

- Oil lubrication pump and reservoir

- Slide-way covers Y & Z-Axis

- Mill head tilts to ±45º forward and back

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Mechanical spindle brake

- Tool box and manual

Includes

- 3-Axis digital readout fitted

- One-shot oil lubrication pump and reservoir

- Drawbar M12 thread

- Coolant system

- Slide-way covers

- X-Axis power-feed

- Halogen light

- Machine vice (150mm)

- Clamp kit

- Safety cutter guard

- Swarf tray

MODEL BM-40V Digital Readout 3-Axis Digital Readout Type Vertical (mm)Table Size 1370 x 254 Spindle Taper - Vertical NT30 (mm)Longitudinal Travel (X-Axis) 860 (mm)Cross Travel (Y-Axis) 360 (mm)Vertical Travel (Z-Axis) 425 Type of Slides Dovetail (mm)Ram Travel 508 (mm)Spindle to Table 505 (mm)Spindle Travel / Diameter 127 / 86 (mm)Throat Depth (max.) 735 Tilting Head (Left ~ Right) ±90º Tilting Head (Forward ~ Back) ±45º (mm/rev)Power Feed - Quill 0.015 / 0.04 / 0.08 (mm/min)Power Feed - Longitudinal (X-Axis) 20 - 2000 (mm/min)Power Feed - Cross (Y-Axis) Optional (mm/min)Power Feed - Vertical (Z-Axis) Optional (inch / mm)Table T-Slot Size 5/8 (kg)Work Table Load Capacity 300 (No./ rpm)Spindle Speeds Vertical Variable (70 - 3500) (kW / hp)Motor Power - Vertical Spindle 2.2 / 3 (V / amp)Voltage / Amperage 415 (cm)Shipping Dimensions (L x W x H) 170 x 150 x 230 (kg)Nett Weight 1300 -

(Please note this item requires a forklift to unload. Please contact us for freight costs)

Features

- 3 Axis digital readout fitted

- 5HP 415V motor with mechanical variable speed system

- NT40 Spindle taper with a chrome & ground quill

- Digital speed readout display for accurate cutter speed

- Hardened & ground work table & slide-ways

- Square construction slides for Y & Z-Axis to maximise rigidity

- Powered elevating motor for Z-Axis

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a rotating base allowing repositioning of spindle

- The ram incorporates a tail lug (spigot) to accept a slotting attachment etc.

- High / neutral and low gear selection lever to maximise torque

- X & Y-Axis power-feed with adjustable micro switch feed stops

- Micro switch on the manual knee handle for additional operator safety

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.04, 0.08, 0.15mm/rev

- Automatic cut off depth stop on quill

- Oil lubrication pump and reservoir

- Slide-way covers Y & Z-Axis

- Mill head tilts to ±45º forward and back

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Mechanical spindle brake

- Tool box and manual

Includes

- 3 Axis digital readout fitted

- Digital speed readout display

- Z-Axis powered elevating motor

- X & Y-Axis power-feeds

- One-shot oil lubrication pump and reservoir

- Machine vice (160mm)

- Clamp kit

- Drawbar M16 thread

- Coolant system

- Slideway covers

- Halogen light

- Safety cutter guard

- Swarf tray

MODEL BM-53VE Digital Readout 3-Axis Digital Readout Type Vertical (mm)Table Size 1370 x 254 Spindle Taper - Vertical NT40 (mm)Longitudinal Travel (X-Axis) 910 (mm)Cross Travel (Y-Axis) 400 (mm)Vertical Travel (Z-Axis) 415 Type of Slides Dovetail (X), Square (Y & Z) (mm)Ram Travel 555 (mm)Spindle to Table 465 (mm)Spindle Travel / Diameter 127 / 86 (mm)Throat Depth (max.) 635 Tilting Head (Left ~ Right) ±90º Tilting Head (Forward ~ Back) ±45º (mm/rev)Power Feed - Quill 0.04 / 0.08 / 0.15 (mm/min)Power Feed - Longitudinal (X-Axis) 20 - 2000 (mm/min)Power Feed - Cross (Y-Axis) 20 - 2000 (mm/min)Power Feed - Vertical (Z-Axis) Rapid (inch / mm)Table T-Slot Size 16 (kg)Work Table Load Capacity 350 (No./ rpm)Spindle Speeds Vertical Variable (50 - 3550) (kW / hp)Motor Power - Vertical Spindle 3.75 / 5 (V / amp)Voltage / Amperage 415 (kg)Nett Weight 1545 -

(Please note this item requires a forklift to unload. Please contact us for freight costs)

(Please note this item requires a forklift to unload. Please contact us for freight costs)Features

- 3 Axis digital readout fitted

- 5HP 415V motor with mechanical variable speed system (50-3350rpm)

- NT40 Spindle taper with a 105mm chrome & ground quill

- Hardened ballscrew X & Y-Axis providing smooth and accurate operation

- 1370mm x 254mm table with 16mm T-slots

- Travels: 890mm longitudinal, 400mm cross, 400mm vertical

- Quill travel:127mm

- Ram travel: 550mm

- Spindle to table: 450mm

- Digital speed readout display for accurate cutter speed

- Hardened & ground work table & slide-ways

- Square construction slides for Y & Z-Axis to maximise rigidity

- Powered elevating motor for Z-Axis

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a rotating base allowing repositioning of spindle

- The ram incorporates a tail lug (spigot) to accept a slotting attachment etc.

- High / neutral and low gear selection lever to maximise torque

- X & Y-Axis power-feed with adjustable micro switch feed stops

- Micro switch on the manual knee handle for additional operator safety

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.04, 0.08, 0.15mm/rev

- Automatic cut off depth stop on quill

- Oil lubrication pump and reservoir

- Slide-way covers Y & Z-Axis

- Mill head tilts to ±45º forward and back

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Mechanical spindle brake

- Tool box and manual

Includes

- 3 Axis digital readout fitted

- Hardened ballscrew X & Y-Axis

- Digital speed readout display

- One-shot oil lubrication pump and reservoir

- X & Y-Axis power-feed

- Z-Axis powered elevating motor

- Machine vice 160mm

- Clamp kit set

- Drawbar M16 thread

- Coolant system

- Slideway covers

- Safety cutter guard

- Halogen light

- Swarf tray

-

(Please note this item requires a forklift to unload. Please contact us for freight costs)

Overview

Manufactured in TaiwanFeatures

- 3 Axis digital readout fitted,

- 5HP 415V motor, inverter control variable speed system with automatic spindle brake (BM-70VE)

- High quality spindle speed control with digital readout

- NT40 Spindle taper with a 105mm chrome & ground quill

- Digital spindle speed readout

- Hardened & ground work table & slide-ways

- Square construction slides for X & Z axis to maximise rigidity

- Turcite B coated X & Y-Axis slide-ways reduces friction for smooth operation

- Pneumatic operation drawbar system for quick and effortless tool change

- Powered elevating motor for Z-Axis

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a rotating base allowing repositioning of spindle

- The ram incorporates a tail lug (spigot) to accept a slotting attachment etc.

- High / neutral and low gear selection lever to maximise torque

- Inverter controlled feed motors on X & Y-Axis

- Micro switch on the manual knee handle for additional operator safety

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.04, 0.08, 0.13mm/rev

- Automatic cut off depth stop on quill

- Automatic oil lubrication pump and reservoir

- Slide-way covers Y & Z-Axis

- Mill head tilts to ±45º forward and back

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Tool box and manual

ORDER CODE M630D MODEL BM-70VE Digital Readout 3-Axis Digital Readout Type Vertical (mm)Table Size 1500 x 305 Spindle Taper - Vertical NT40 (mm)Longitudinal Travel (X-Axis) 1050 (mm)Cross Travel (Y-Axis) 420 (mm)Vertical Travel (Z-Axis) 500 Type of Slides Dovetail (X), Square (Y & Z) (mm)Ram Travel 485 (mm)Spindle to Table 460 (mm)Spindle Travel / Diameter 155 / 105 (mm)Throat Depth (max.) 750 Tilting Head (Left ~ Right) ±90º Tilting Head (Forward ~ Back) ±45º (mm/rev)Power Feed - Quill 0.04 / 0.08 / 0.13 (mm/min)Power Feed - Longitudinal (X-Axis) 30 - 3000 (mm/min)Power Feed - Cross (Y-Axis) 30 - 3000 (mm/min)Power Feed - Vertical (Z-Axis) Rapid (inch / mm)Table T-Slot Size 5/8 (kg)Work Table Load Capacity 500 (No./ rpm)Spindle Speeds Vertical Inverter (70 - 4200) (kW / hp)Motor Power - Vertical 3.75 / 5 (V / amp)Voltage / Amperage 415 (cm)Shipping Dimensions (L x W x H) 160 x 170 x 240 (kg)Nett Weight 1800 -

Contact us for current pricing.

Overview

Manufactured in TaiwanFeatures

- 3-Axis Digital Readout fitted

- 5HP 415V motor on vertical spindle, Inverter control variable speed system (BM-90HV)

- 5HP 415V motor on horizontal spindle, Speeds control by gear selection levers

- Hardened ballscrew X & Y-Axis providing smooth and accurate operation

- Japanese Quality Yaskawa Spindle speed control

- NT40 vertical spindle taper with a 110mm chrome & ground quill

- NT40 horizontal spindle taper

- Servo controlled feed motors on X & Y-Axis ensures response, accuracy and consistent feed

- Hardened & ground work table & slide-ways

- Square construction slides for X & Z-Axis to maximise rigidity

- Turcite B coated X & Y-Axis slide-ways reduces friction for smooth operation

- Pneumatic operation drawbar system for quick and effortless tool change

- Powered elevating motor for Z-Axis

- Large 1470mm x 370mm work table

- Electric fan incorporated in milling head to reduce heat

- Meehanite casting for high strength & minimal deformation

- Quality electrics & overload protection in an easy access enclosure

- Horizontal travelling ram mounted on a solid base allowing repositioning of spindle

- High / neutral and low gear selection lever to maximise torque

- Micro switch on the manual knee handle for additional operator safety

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Automatic quill feed 0.35, 0.07, 0.14mm/rev

- Automatic cut off depth stop on quill

- Automatic oil lubrication pump and reservoir

- Table trays each end of work table

- Clutch hand wheels X & Y-Axis

- Steel slide-way cover Y-Axis

- Mill head tilts to ±90º left and right

- Manual quick action quill lever

- Toolbox and Manual

ORDER CODE M633D MODEL BM-90HV Digital Readout 3-Axis Digital Readout Type Vertical & Horizontal (mm)Table Size 1470 x 370 Spindle Taper - Vertical NT40 Spindle Taper - Horizontal NT40 (mm)Longitudinal Travel (X-Axis) 1120 (mm)Cross Travel (Y-Axis) 520 (mm)Vertical Travel (Z-Axis) 440 Type of Slides Dovetail (X), Square (Y & Z) (mm)Ram Travel 600 (mm)Spindle to Table 505 (mm)Spindle Travel / Diameter 140 / 110 (mm)Throat Depth (max.) 785 Tilting Head (Left ~ Right) ±90º Tilting Head (Forward ~ Back) Fixed (mm/rev)Power Feed - Quill 0.035 / 0.07 / 0.14 (mm/min)Power Feed - Longitudinal (X-Axis) 30 - 3000 (mm/min)Power Feed - Cross (Y-Axis) 30 - 3000 (mm/min)Power Feed - Vertical (Z-Axis) Rapid (inch / mm)Table T-Slot Size 18 (kg)Work Table Load Capacity 600 (No./ rpm)Spindle Speeds Vertical Inverter (60 - 3600) (No./ rpm)Spindle Speeds Horizontal 9 (65 - 1500) (kW / hp)Motor Power - Vertical 3.75 / 5 (kW / hp)Motor Power - Horizontal 3.75 / 5 (V / amp)Voltage / Amperage 415 (cm)Shipping Dimensions (L x W x H) 207 x 190 x 250 (kg)Nett Weight 2725 -

Features

- Ideal for home or maintenance workshop use

- Geared head drill & mill machine with 3 morse taper spindle

- 6 drilling speeds from 95-1650rpm

- Thread tapping function

- Coolant pump system with flexible hose

- Micro down feed adjustment

- Mill head tilts to ±90º

- Milling table travels 480 x 200mm

- Swivel safety drilling chuck guard

- Emergency stop switch and overload protection

- Adjustable accurate depth setting for increased productivity

- Rack and pinion wind-up table

- Rack and pinion wind-up drill head

- Thick walled column ensuring greater rigidity

- Concertina slide way cover on y axis

- Adjustable gibs on table

- 14mm T slotted work table and base

- 1.5kW 240V motor

Includes

- Face milling cutter with inserts

- 13mm keyed drill chuck and arbor

- Chuck key to suit

- MT3 to MT2 drill sleeve adapter

- Drill drift tool to remove drill chuck or taper shank drills

- M12 x 1.75mm drawbar

- 1/2" x 12TPI drawbar

- Safety cutter guard

Type Vertical (mm)Table Size 730 x 210 Column Type Ø125mm Spindle Taper - Vertical 3MT (mm)Longitudinal Travel (X-Axis) 480 (mm)Cross Travel (Y-Axis) 200 (mm)Vertical Travel (Z-Axis) 850 Type of Slides Dovetail (mm)Spindle to Table 630 (mm)Spindle Travel / Diameter 120 / 75 (mm)Throat Depth (max.) 280 Tilting Head (Left ~ Right) ±90º Tilting Head (Forward ~ Back) Fixed (mm)Drilling Capacity 31.5 (mm)End Milling Capacity 28 (mm)Face Milling Capacity 80 (mm/min)Power Feed - Longitudinal (X-Axis) Optional (inch / mm)Table T-Slot Size 14 (kg)Work Table Load Capacity 55 (No./ rpm)Spindle Speeds Vertical 6 (95 - 1650) (kW / hp)Motor Power - Vertical Spindle 1.5 / 2 (V / amp)Voltage / Amperage 240 / 10 -

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)Overview

The HM-46B milling machines is similar in overall size to the popular RF-31 or HM-32 but with the additional benefit of a 6-speed 95-1600rpm, gear driven head which can be tilted up to 90º either side of the vertical. This feature allows the head to be positioned in a variety of positions, allowing a whole range of milling, slotting, grooving, drilling and boring operations to be carried out. The usual handle-driven down feed is available for precision drilling and there is a fine manual down-feed control for precise vertical milling. The motor is controlled by a separate forward and reverse on/off button switches. There is a heavy duty steel stand available as an extra, strongly recommended bearing in mind the weight of the machine. Also available is a optional power feed attachment which fits to the left hand end of the table and provides a smooth, variable speed longitudinal drive.Features

- 3-Axis digital readout counter fitted with 2-Axis X & Y scales only

- Gear driven head 6 speeds

- Dovetail vertical Z-axis

- Mill head tilts to ±90º from vertical with digital display

- Large 730 x 210mm ground work table with T-slots

- Adjustable leadscrew nuts eliminating backlash on both axis

- Fine feed hand wheel operating quill feed

- Forward and reverse on/off button switches

- Digital tilting head gauge

- 3MT spindle with 75mm diameter quill

- Adjustable table and drill length stops

- Rack and pinion wind-up head

- Rear slide-way cover and slide clamps on all axis

- Spindle lock for quill

- Table lock on both axis

- Metric dial graduations @ 0.05mm for X & Y axis

Includes

- 3-Axis digital readout counter fitted with 2-Axis X & Y scales only

- Digital tilting head gauge

- Drill chuck & arbor

- Face cutter & arbor

- Safety cutter guard

- M12 draw bar

- 1/2" x 12tpi whitworth draw bar

ORDER CODE M138D MODEL HM-46B Digital Readout 3-Axis Counter, X, Y Scales Type Vertical (mm)Table Size 730 x 210 Column Type Dovetail Spindle Taper - Vertical 3MT (mm)Longitudinal Travel (X-Axis) 485 (mm)Cross Travel (Y-Axis) 175 (mm)Vertical Travel (Z-Axis) 430 Type of Slides Dovetail (mm)Spindle to Table 485 (mm)Spindle Travel / Diameter 120 / 75 (mm)Throat Depth (max.) 265 Tilting Head (Left ~ Right) ±90º Tilting Head (Forward ~ Back) Fixed (mm)Drilling Capacity 31.5 (mm)End Milling Capacity 28 (mm)Face Milling Capacity 80 (mm/min)Power Feed - Longitudinal (X-Axis) Optional (inch / mm)Table T-Slot Size 14 (kg)Work Table Load Capacity 55 (No./ rpm)Spindle Speeds Vertical 6 (95 - 1600) (kW / hp)Motor Power - Vertical 1.5 / 2 (V / amp)Voltage / Amperage 240 / 10 (cm)Shipping Dimensions (L x W x H) 102 x 102 x 143 (kg)Nett Weight 380 -

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)

Price is ex-Adelaide (Please note this item requires a forklift to unload. Please contact us for freight costs)Overview

This HM-54GV geared head vertical and horizontal turret milling machine now includes a inverter variable speed drive on the vertical spindle, with a powerful continuous-load 2.2kW / 3hp vertical motor and a 2hp motor for the horizontal spindle, intended for trade use. The work table is precision made with adjustable dovetail guides and is recognised for its 600mm X axis by 200mm Y axis travel. There is a three armed handle on the side for drilling also incorporating a fine feed control hand wheel on the front for milling. The hi-low geared head selector lever mounted on right side of milling head allows for quick change off speed range. Other features include 3-Axis digital readout system, taper roller bearing support for the spindle, easy-to-read drilling depth stop, low voltage LED work light, coolant system, X axis power feed unit, drill chuck, 1" & 1-1/4" horizontal arbors, 2 & 3 morse taper adaptors. The combination of generous sized vertical support and rugged cast iron construction throughout reduces vibration and guarantees accurate and chatter-free operation. Extra Features: Swivel table 1" & 1-1/4" horizontal arborsFeatures

-

- Electronic inverter variable spindle speeds

- 3 Axis digital readout system

- Swivel table left & right with graduated scale

- Mill head tilts to ±45º left to right

- 450mm horizontally sliding and rotating ram

- NT30 Horizontal and vertical spindles that are hardened and ground

- Precision-ground dovetail slide-ways and table

- Precision milling table incorporating machined T slots

- Rear concertina slide-way cover

- Forward and reverse button switch

- Fine hand wheel operated quill feed

- Swarf & splash tray

- Spindle lock for quill

- Metric dial graduations @ 0.02mm for X , Y & Z-Axis

- Vertical quill hand-wheel dial graduations @ 0.05mm

- All slides utilise dovetail construction for maximum rigidity

- Includes 1" & 1-1/4" arbors for the horizontal spindle

- * Note: X & Y travels maybe reduced due to digital readout scales and safety stops

- * Note: Optional Y & Z power feeds require additional parts & fitting (not included)

Includes

- Electronic inverter variable spindle speeds

- 3 Axis digital readout system

- X-Axis power-feed

- Safety cutter guard

- Swarf tray

- Coolant system

- LED work light

- Drill chuck & arbor

- NT30 to 3MT adaptor

- 2MT & 3MT adaptors

MODEL HM-54GV Digital Readout 3-Axis Digital Readout Type Vertical & Horizontal (mm)Table Size 1000 x 240 Spindle Taper - Vertical NT30 Spindle Taper - Horizontal NT30 (mm)Longitudinal Travel (X-Axis) 600* (mm)Cross Travel (Y-Axis) 200* (mm)Vertical Travel (Z-Axis) 340 Type of Slides Dovetail (mm)Ram Travel 450 (mm)Spindle to Table 375 (mm)Spindle Travel / Diameter 120 / 90 (mm)Throat Depth (max.) 640 Tilting Head (Left ~ Right) ±45º Tilting Head (Forward ~ Back) Fixed (mm)Drilling Capacity 40 (mm)End Milling Capacity 25 (mm)Face Milling Capacity 80 (mm/rev)Power Feed - Quill Manual (mm/min)Power Feed - Longitudinal (X-Axis) 20 - 2000 (mm/min)Power Feed - Cross (Y-Axis) Optional * (mm/min)Power Feed - Vertical (Z-Axis) Optional * (inch / mm)Table T-Slot Size 14 (kg)Work Table Load Capacity 160 (No./ rpm)Spindle Speeds Vertical Variable (100 - 2000) (No./ rpm)Spindle Speeds Horizontal 9 (60 - 1350) (kW / hp)Motor Power - Vertical 2.2 / 3 (kW / hp)Motor Power - Horizontal 1.5 / 2 (V / amp)Voltage / Amperage 240 / 10 (cm)Shipping Dimensions (L x W x H) 134 x 114 x 225 (kg)Nett Weight 900 -

-

Stand to suit M138D Mill Drills

Features

- Side access door for storing parts

- Rigid design to withstand 395kg mill drill

- Top Tray has 4 x bolt holes for securing mill drill to stand

- Base has bolt 4 x holes to secure to floor

- Top tray has provisions for coolant return line

- Includes base mounted tray inside stand